Ribs are ready to be riveted on to spar

I started the day out with drilling the systems holes in the wing ribs. There were a lot of holes to drill, so I set up a couple of work stops on the mill and was able to knock out drilling the holes pretty quick. Then the holes need to be deburred. In the afternoon Wendy joined in and helped me get the hole deburring finished. Then we scuffed/cleaned the ribs and brackets parts and in preperation for priming. We then setup all the parts for each wing one and primed them in batches. Wendy was a big help. After the primer dried I riveted on the flap hinge brackets and the torque tube assemblies.

Drilling pilot holes for the systems holes. I used the workstop on the left to position the part in the X axis and the fixed jaw to position it in the Y.

Next I enlarged the holes to the appropriate size, based on the size of the snap bushing that is to get installed

After we finished deburing it was time to scuff and clean the ribs. Wendy was a big help

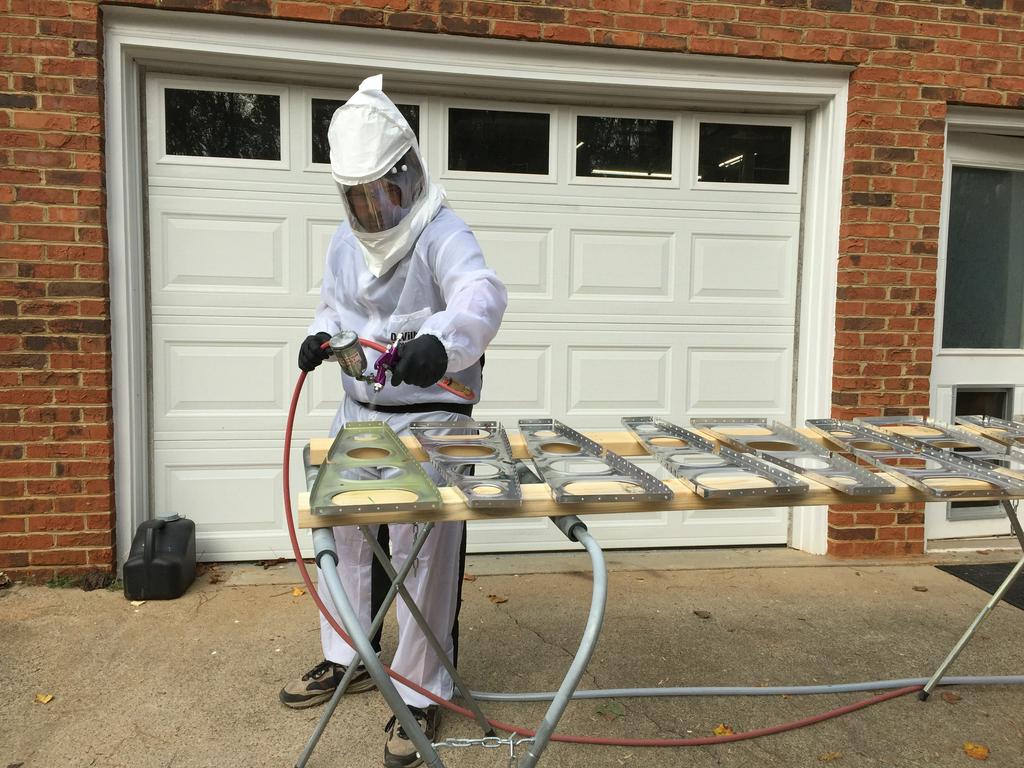

We setup all the parts for the left wing, primed them and then setup parts for the right wing.

Then I put on my space suit and got to spraying

After the primer dried I riveted on the Flap hinge brackets

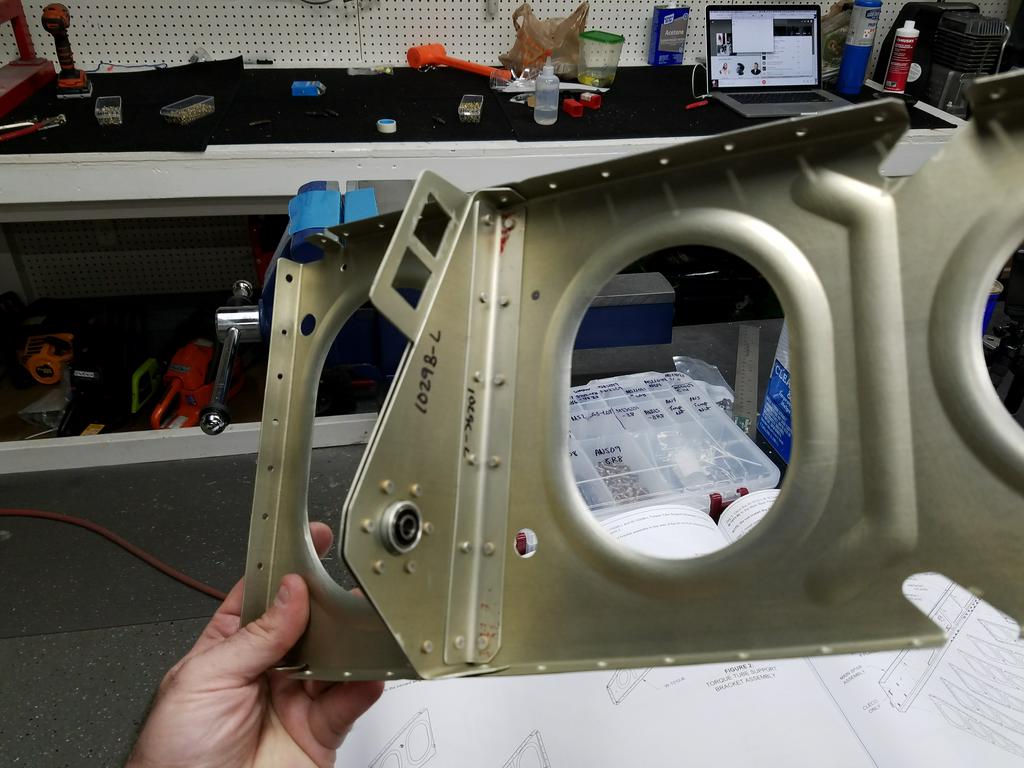

Next I riveted the torque tube assemblies together

Then I riveted the torque tube assemblies to the inboard ribs