Today I cut the hole in the bottom skin for the Gretz pitot mast and fabricated the doubler plates and reinforcement angle. This all had to be self engineered so the process was slow moving, but everything came out good. I ordered some White powder coating to finish the pitot mast. It should be here Tuesday. I also drilled another hole in the first few wing ribs and relocated the magnometer wiring to the new hole. Now the pitot and aoa lines don’t have to share a hole with any wiring. The AOA and the magnometer could have shared one hole, but it was real tight and I was having trouble getting the AOA line through the snap bushings with the wires there. I was worried if I ever had to replace the AOA line it would be almost impossible to run it through the the hole with the bottom skins riveted in place.

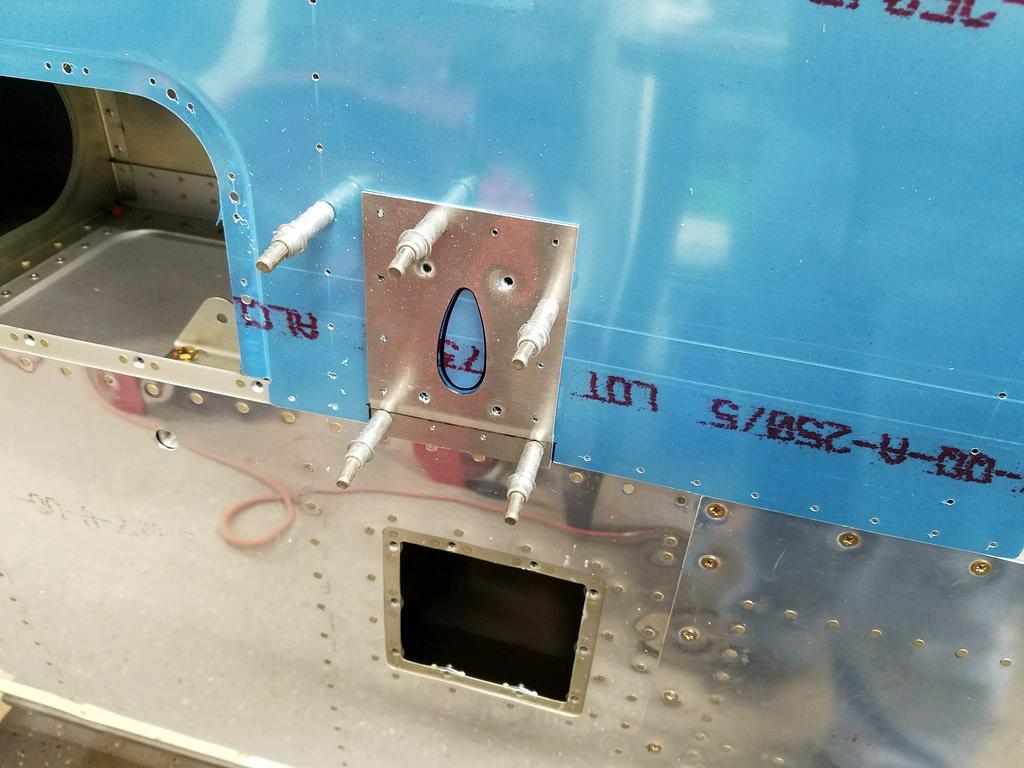

Setting up the pitot mast doubler bracket and reinforcement angle

Match drilled the doubler plate to the bottom wing skin

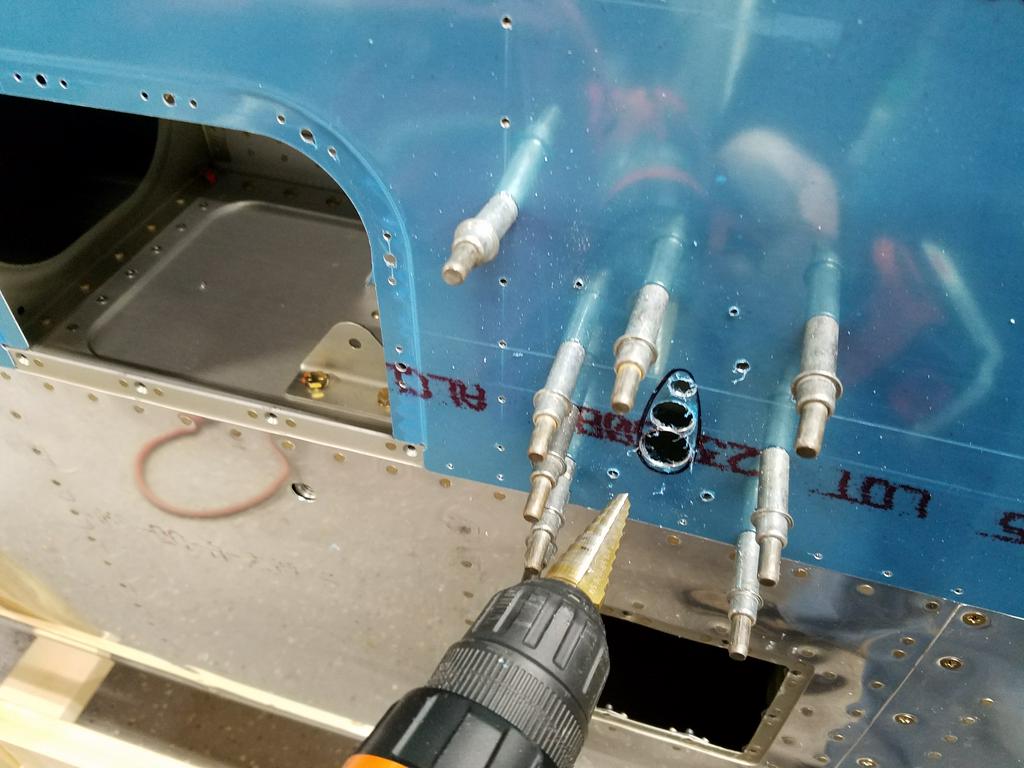

Pilot drilling holes for the mast cutout

The mast profile cut out

Got the mast cleaned and scuffed. Went to powder coat it and realized I didn't have any White powder...I ordered some from McMaster. It should be here Tuesday

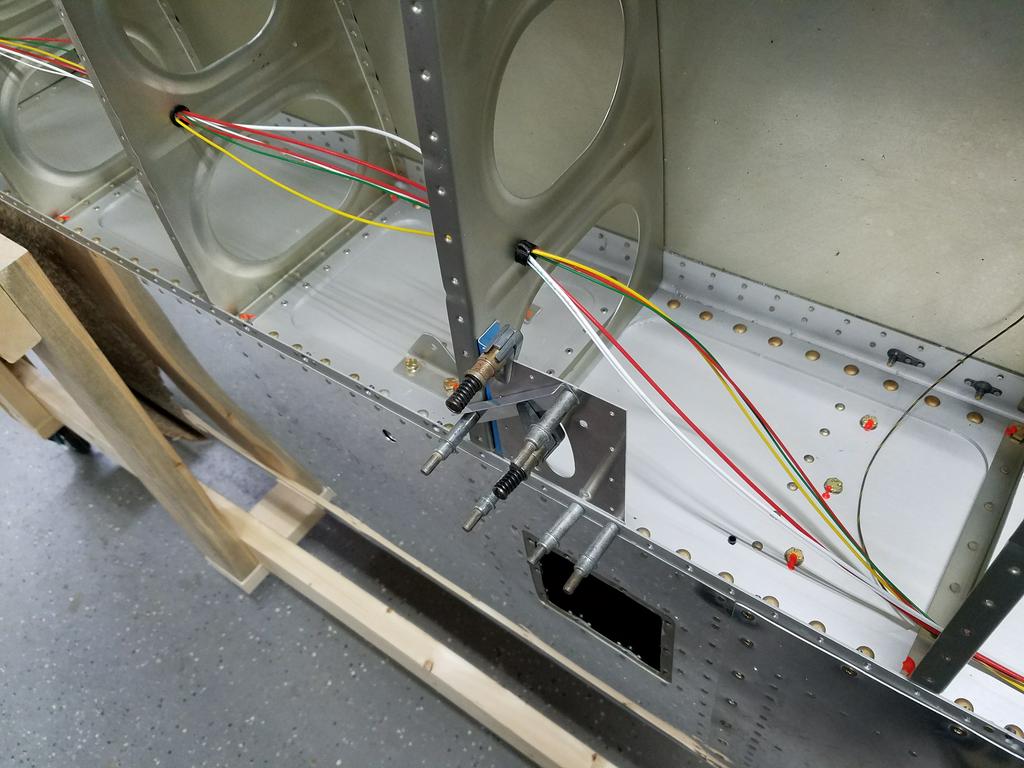

The pitot and aoa lines run