Continued work on the flaps

Today I started the day of prepping the flap ribs. All holes need to be drilled to size and the edges deburred. Then I clecoed the flap structure together in preparation for various drilling operations later in the day. Next I fabricated the trailing edges. Then I clecoed the flap assemblies together with the skins in order to perform some drilling operations. After that was complete I disassembled the flap assemblies and countersunk the trailing edges. All that’s left prior to riveting is dimpling and priming. Hopefully I’ll get that knocked out tomorrow.

Drilling holes in the ribs to size

Wing skeleton clecoed together

Cutting a section of the trailing edge to size

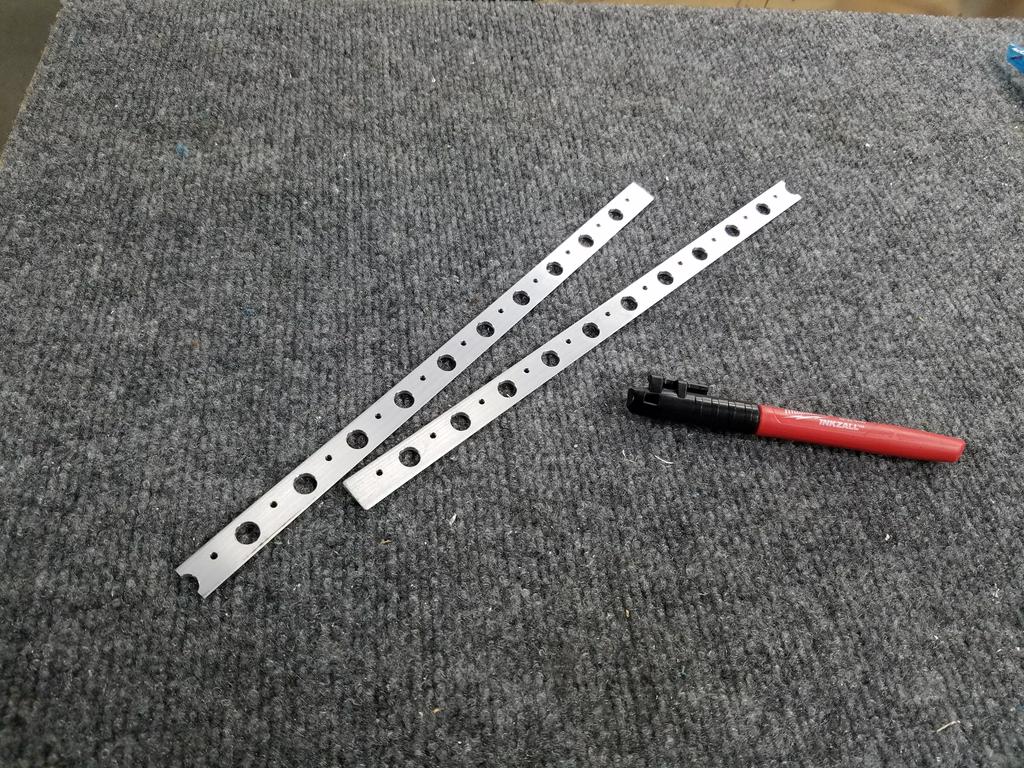

Outboard trailing edge pieces

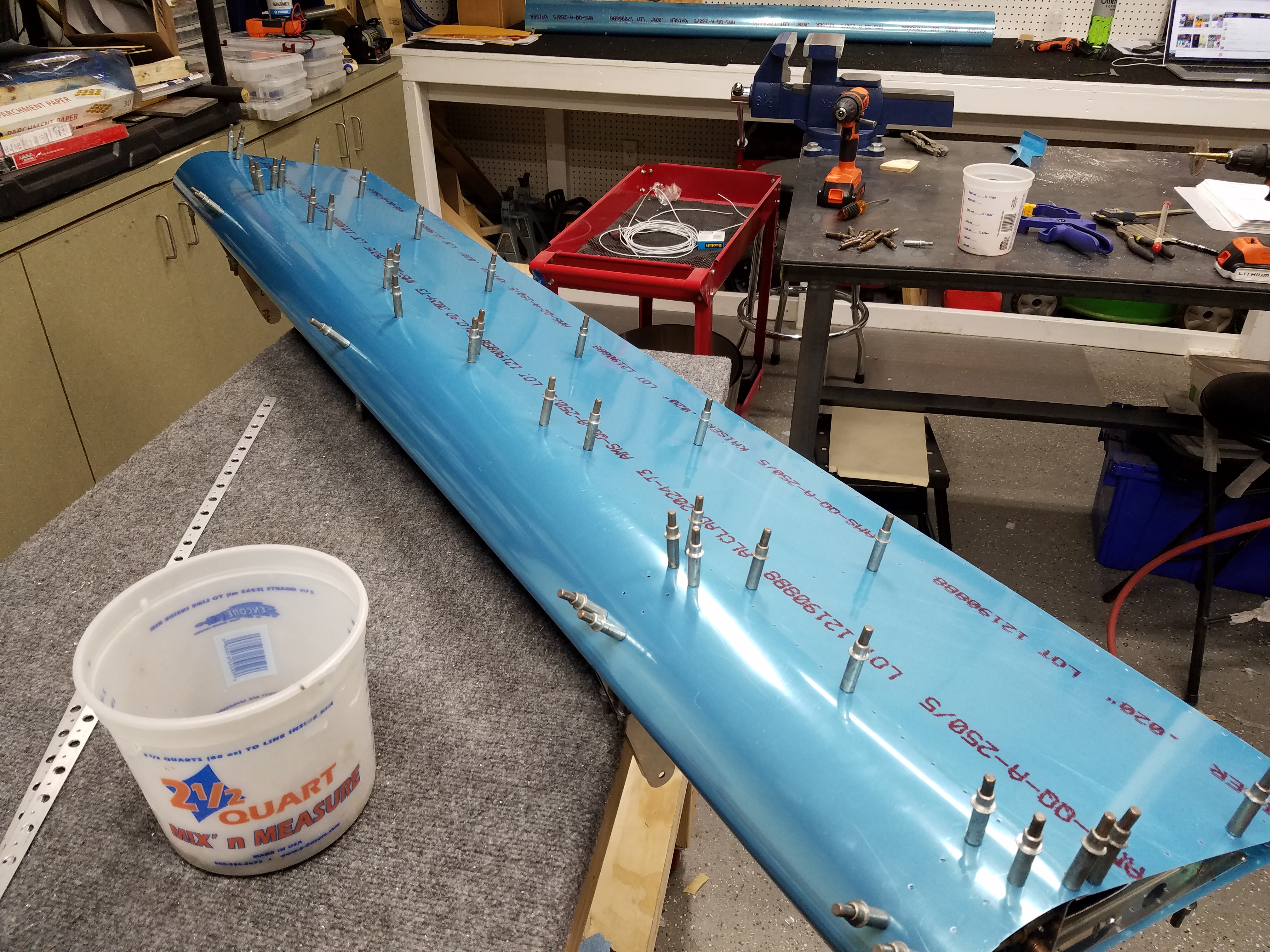

Flap assembly clecoed together for drilling operations

Trailing edge countersunk